Introduction

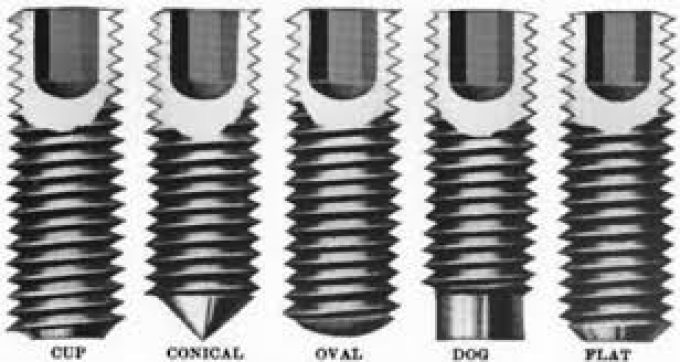

Set screws, those tiny, unassuming components, play an indispensable role in various mechanical applications. Among the myriad types available, the flat point set screw stands out as a versatile and essential fastener. In this article, we’ll delve into the world of flat point set screws, exploring their uses, benefits, and answering frequently asked questions about these little marvels.

FAQ

Q1: What is a Flat Point Set Screw?

A flat point set screw is a threaded fastener typically made of steel or stainless steel, used to secure an object within another by exerting pressure and friction. The distinguishing feature is its flat point, designed to apply pressure evenly on the surface it contacts.

Q2: Where Are Flat Point Set Screws Used?

Flat point set screws are used in a wide range of applications, such as:

- Manufacturing: In assembly of machinery and equipment.

- Automotive: Securing parts and components.

- Electronics: Fixing small components on circuit boards.

- Woodworking: For joinery and assembly.

- Aerospace: Critical fasteners in aircraft and spacecraft.

- Construction: In structural and architectural work.

Q3: What Are the Advantages of Using Flat Point Set Screws?

Flat point set screws offer several benefits:

- Minimal Surface Damage: Their flat points distribute pressure evenly, reducing the risk of surface damage compared to other screw types.

- Precise Alignment: The flat tip allows for precise alignment and prevents wobbling during installation.

- Versatility: They can be used with various materials, including metal, wood, and plastic.

- Secure Fastening: Flat point set screws provide a strong grip, ensuring components stay firmly in place.

Q4: What Sizes Are Available?

Flat point set screws come in a range of sizes, with thread diameters typically ranging from 1/16″ to 1″. Lengths vary to accommodate different applications. When selecting a size, consider the specific requirements of your project.

Q5: How Do You Install Flat Point Set Screws?

- Preparation: Ensure that the surfaces are clean and free from debris. Insert the screw into the pre-drilled hole.

- Alignment: Position the flat point against the surface you want to secure.

- Tightening: Using an appropriate tool, turn the set screw clockwise to secure it in place. Apply the necessary torque, but be cautious not to over-tighten, as it can damage the material.

- Double-Check: After installation, double-check that the object is secure, and there is no unwanted movement.

Q6: What Tools Are Needed for Installation?

To install flat point set screws, you typically need:

- Hex Key (Allen Wrench): This tool is most commonly used for set screw installation.

- Screwdriver: Flathead or Phillips screwdrivers may be used for some applications.

- Torque Wrench: Useful for precise tightening to a specified torque level.

Conclusion:

Flat point set screws are unsung heroes of the mechanical world, providing reliable and secure fastening in countless applications. Their flat tips, versatility, and ease of installation make them a valuable addition to any toolkit. Understanding their features and how to use them properly can greatly enhance the efficiency and longevity of your projects. So, whether you’re a DIY enthusiast or a professional, consider the flat point set screw for your fastening needs.